3.

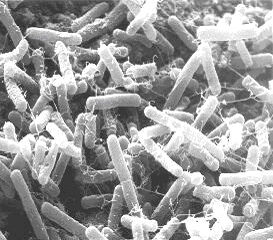

Dark-fermentation by bacteria

Hundreds of bacterial strains can produce hydrogen by (dark) anaerobic fermentation of chemical compounds. The [FeFe]-hydrogenases, then, function to dispose of excess electrons accumulated during fermentation (Peters, 1999). Carbohydrates are the most attractive substrates but proteins, organic acids and alcohols may also be used. These bacteria are either facultative anaerobic or strict anaerobic (oxygen being toxic for growth). The highest hydrogen producers amongst facultative anaerobic bacteria are the enterobacteriaceae species. Their typical conversion efficiency is about 0,85 mol H2/mol hexose. Typical conversion efficiencies of the strict anaerobic hydrogen producers, mainly Clostridium species, are 1.9–2.5 mol H2/mol hexose (Lay, 2001; Ueno et al., 2001; Fang and Liu, 2002). In one study, continuous H2 production achieved a yield of 2.7 mol H2/glucose using a mixed culture of Clostridium butyricum and Enterobacter aerogenes (Yokoi et al., 2002).

Clostridium Enterobacter

The biogas contains about 50% and

70% hydrogen, respectively, and carbon dioxide as other major component. Traces

compounds are also present in the biogas. However, they have a relatively low

effect, if any, on the biogas end-user. Indeed, according to experimentations

carried out at CWBI,

direct feeding of a PEM fuel cell with biogas

(0,8-liter per hour, 70% H2 – 30% CO2) was successful. As shown on

Figure 2, acid and alcohol compounds are sub-products of

carbohydrates metabolism. However, as demonstrated at CWBI with pure

Clostridium strains, successive removal of a specific fraction of

sub-product mixtures and addition of fresh medium can lead to the production of

the sole acetate and butyrate metabolites. Furthermore, they can be degraded by

classical

biomethanization. Therefore, no

inhibitory compounds would be produced by H2 - producing bacteria

Different optimisation factors have been investigated in literature and

by CWBI. The most critical affecting hydrogen production rates and yields is H2

partial pressure (Mizuno et al., 2000).

In classical hydrodynamic conditions i.e. gentle mixing without

gas stripping, the maximum hydrogen production rate achieved per unit of

bioreactor volume is generally about 10-15 mmol H2/l.h. Indeed, most

of these studies emphasize that biogas transfer out of the liquid phase is

limited in aqueous reactors without intensive stirring (Rachman et

al., 1998). However, while stirred reactors facilitate gas

release from the liquid phase, continuous stirring of the reactor consumes

considerable electric power. The energy needed for mixing in anaerobic

wastewater treatment reactors ranges from 85 to 105 kW/1000 m³ (Grady et al.,

1999).

Aiming at a better biogas transfer, it has been found in

batch tests that continuous release of the biogas from the system can increase H2

yields by as much as 40% (Logan et al., 2002). Results of the experiments

carried out in the CWBI have achieved H2 production rate six times

higher when CO2 was continuously injected in medium during glucose

fermentation in 15L bioreactor. However, since inert gas such as CO2

present in biogas is unfavourable for the hydrogen end-users yields, such as PEM

fuel cell, gas stripping should be avoided. Other important physico-chemical

parameters to master are pH, temperature, and concentrations in organic or

ammonium nitrogen and sub-products.

Various types of bioreactors have been studied for biohydrogen production by dark fermentation of carbohydrates e.g.

batch :

Van Ginkel et al., 2001; Logan et al., 2002; Oh et al., 2003,

fed-batch : Chin et al., 2003,

continuous-flow stirred tank : Fang and Liu, 2002; Hussy et

al., 2003,

upflow granulated reactors : Liu and Fang, 2003, Chang and

Lin, 2004

membrane bioreactor : Oh et al., 2005

saturated packed-bed column reactors : Rachman et al.,

1998; Yokoi et al., 1997; Chang et al., 2002; Palazzi et al., 2002;

Lee et al., 2003, Wu et al., 2005

unsaturated trickle bed reactor : Oh et al., 2004, Zhang et

al., 2006.